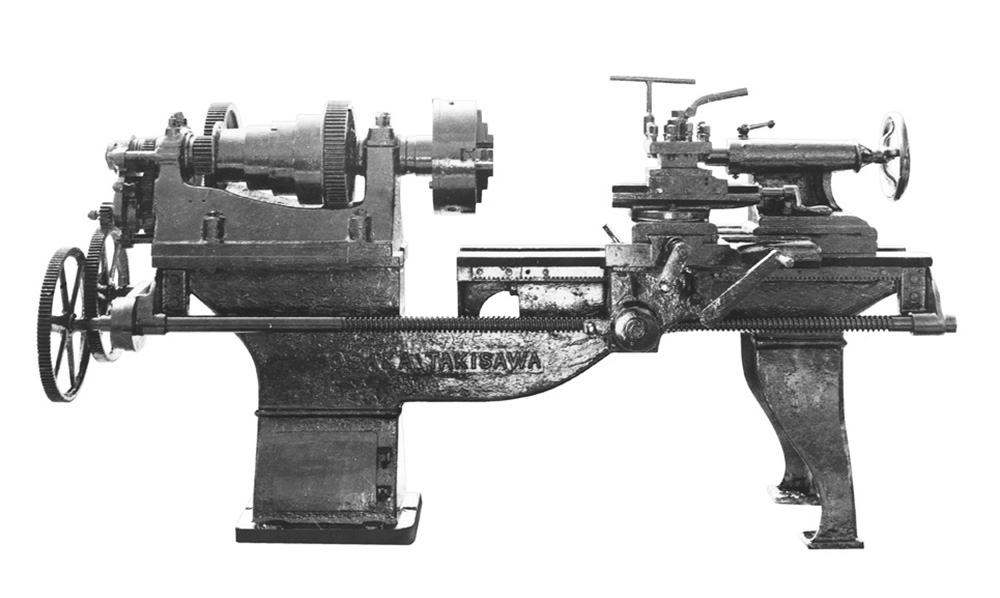

| 1922 |

Manual latheCone pulley lathe Manual latheCone pulley lathe

This cone pulley lathe built the foundation of the TAKISAWA brand. This is where Takisawa Machine Tool started. |

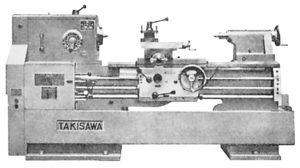

| 1958 |

Manual latheTAL-6/8 Manual latheTAL-6/8

The manual lathe TAL series is still being manufactured today. |

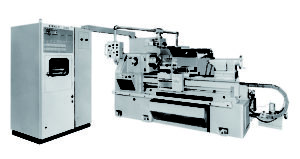

| 1968 |

Manual latheTAL-N Manual latheTAL-N

This lathe was developed as the pioneer NC lathe in Japan. |

| 1973 |

Manual latheMORANDO 3PR 9 Manual latheMORANDO 3PR 9

This large lathe was produced through a technical tie-up with a world-scale large lathe manufacturer in Italy. |

| 1975 |

CNC latheNX-540 CNC latheNX-540

This is the first CNC lathe that adopted DC servomotor for positioning control. Many were sold overseas as well. |

| 1978 |

CNC latheTX-2 CNC latheTX-2

A chucker providing better accessibility to the chuck. The layout of this lathe is the base of present CNC lathes. |

| 1980 |

CNC latheTS-15 CNC latheTS-15

This lathe, equipped with a slant bed for discharging chips smoothly, was called “World famous machine”. With the production of this lathe, TAKISAWA’s technical capability developed significantly. |

| 1981 |

Machining centerMAC-V2 Machining centerMAC-V2

Full-scale entry into the machining center market. Equipped with a high-speed spindle of 10000 min-1,MAC-V2 boasted its high accuracy clearing the NASA standard while balancing its performance and cost. Afterward, it represented the high technical capability of TAKISAWA. This machine also contributed to open up other than the automobile field. |

| 1982 |

CNC latheTS-40/50 CNC latheTS-40/50

A large CNC lathe having a slant bed and capable of 820 mm swing. |

| 1983 |

CNC latheTC-2 CNC latheTC-2

Remarkably space-saving machine having the control unit incorporated in its upper part. As being highly accurate, low-priced, and compact, the best-selling TC series has been sold over 30,000 units worldwide. |

| 1983 |

CNC latheTF-20 CNC latheTF-20

1-spindle, 2-turret CNC lathe. With the upper and lower turrets, it realized highly-efficient machining. |

| 1986 |

Vertical CNC latheTK-2 Vertical CNC latheTK-2

This vertical CNC lathe series enables machining of odd-form workpieces, which is difficult for horizontal CNC lathes. |

| 1987 |

Combined machining CNC latheTM-20 Combined machining CNC latheTM-20

This CNC lathe with opposed twin spindle has led to the current TS-4000. |

| 1988 |

Piston machineTPS-3000 Piston machineTPS-3000

The TPS series has enabled high-speed cutting of oval workpieces such as pistons of automobiles. This series has been used by the world’s three major piston production groups including the F1 top team. |

| 1989 |

Multi-tasking machineTM-15 Multi-tasking machineTM-15

A multi-tasking machine with opposed twin spindle and upper/lower turrets. |

| 1990 |

CNC latheTX-20G CNC latheTX-20G

A built-in type high-speed gantry loader developed ahead of other companies to meet the needs for manpower saving.

It is servo-controlled by NC, without using conventional cylinders and geared motors. The space-saving design of transferring workpieces along the ceiling was also revolutionary. |

| 1993 |

CNC/manual latheTAC-510 CNC/manual latheTAC-510

An NC unit is incorporated into the manual lathe that has supported the TAKISAWA’s history. This next-generation manual lathe is named TAC series with RAKU-RAKU Expert system. |

| 1996 |

Machining centerMAC-V40 Machining centerMAC-V40

This machining center is still being sold today. It has a dual contact spindle that enables heavy-duty cutting. |

| 2000 |

Parallel twin-spindle CNC latheTT-200 Parallel twin-spindle CNC latheTT-200

The TT series lathe, which consists of two CNC lathes and a gantry loader as standard, supports automation. It can increase the efficiency of mass production in the automobile industry, etc. |

| 2001 |

CNC latheTC-200 CNC latheTC-200

An 8-inch CNC lathe that has been continuously evolving as the current TCN series. Since TC-200, the series has almost reached the current shape. |

| 2002 |

Multi-tasking machineTMM-250M3 Multi-tasking machineTMM-250M3

Equipped with a tool spindle, this model can perform full-scale combined machining under simultaneous 5-axis control. |

| 2009 |

CNC latheTG-6000 CNC latheTG-6000

A large CNC lathe of high rigidity and high accuracy, which is the successor of the great machine TS-50. |

| 2011 |

CNC/manual latheTAC-1500 CNC/manual latheTAC-1500

This lathe has the maximum swing over bed of 1500 mm and the maximum turning length of 6000 mm. With the introduction of this lathe, the TAC series can now cover a wide range of workpieces from small to large or long. |

| 2011 |

Multi-tasking machineTMT-4500 Multi-tasking machineTMT-4500

Having the highest cutting capabilities of machining center and CNC lathe, this ultimate multi-tasking machine far exceeds the conventional productivity with their functions integrated in it. |

| 2012 |

Multi-tasking machineTMX-2000 Multi-tasking machineTMX-2000

A multi-tasking machine that has a tool spindle and is developed under the latest concept of orthogonal coordinate. |

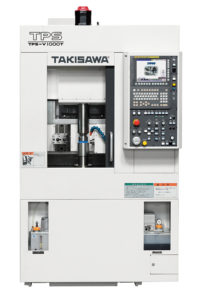

| 2015 |

Vertical piston machineTPS-V1000T Vertical piston machineTPS-V1000T

Its vertical structure has achieved the smallest machine width of 1180 mm in its class and significantly enhanced capability. This machine received the Technical Award from the Chugoku-Shikoku Branch of the Japan Society for Precision Engineering. |

| 2016 |

Shaft machine toolTF-2600 Shaft machine toolTF-2600

TAKISAWA’s first shaft machining tool. |

| 2016 |

Multi-tasking machineTM-4000 Multi-tasking machineTM-4000

Compact multi-turret type multi-tasking machine series. |

| 2018 |

Parallel twin-spindle CNC latheTT-1100G Parallel twin-spindle CNC latheTT-1100G

A completely new loading system was developed, achieving high-speed loading time of 1.7 seconds. |

| 2018 |

Multi-tasking machineTMX-4000 Multi-tasking machineTMX-4000

Newly developed multi-tasking machine with a tool spindle. |

| 2020 |

Parallel twin-spindle CNC latheTT-2100HP Parallel twin-spindle CNC latheTT-2100HP

The axis linear guide and the direct measuring system (patented) have realized high accuracy machining for even longer time. |

| 2021 |

Robot systemTR-10W Robot systemTR-10W

Robot system:TR-10W

The robot system has been introduced to respond to various needs for automation. It realizes automation using a robot by simple operation. |